Automatisches Gaskupplungssystem

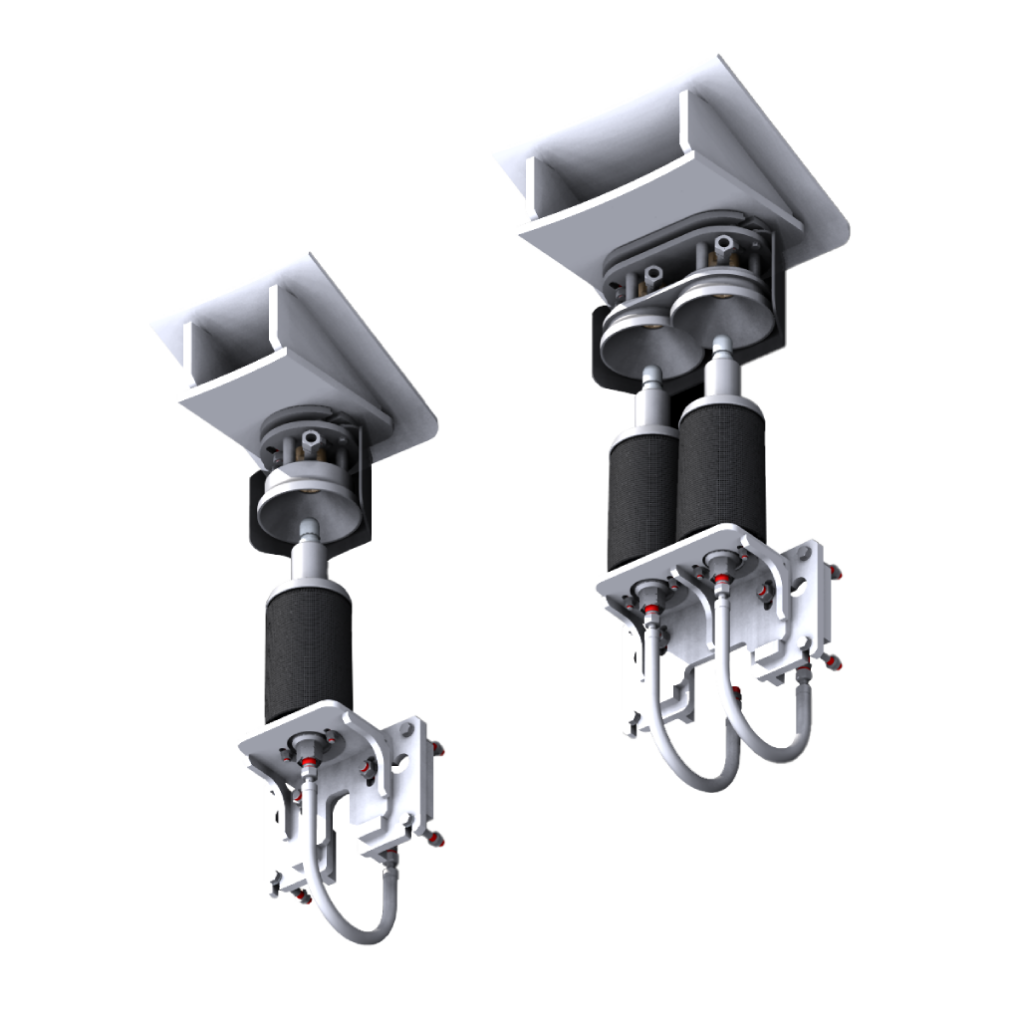

qoupler G

Der qoupler G ermöglicht das automatische Ankoppeln der Gasversorgung an die Stahlwerkspfannen. Er erhöht die Sicherheit des Bedieners und gewährleistet eine sichere und zuverlässige Verbindung.

qoupler G ist ein fortschrittliches automatisches Gaskupplungssystem, das Geschwindigkeit, Sicherheit und Zuverlässigkeit garantiert. Es ist auf anspruchsvolle Umgebungen wie Stahlwerke zugeschnitten und garantiert optimale Leistung unter rauen Bedingungen. Das System lässt sich leicht installieren und an bestehende Anlagen anpassen, was einen reibungslosen Betrieb und eine reibungslose Wartung gewährleistet.

Das System eignet sich für alle Pfannengrößen und Durchflussanforderungen und koppelt bis zu drei Versorgungsleitungen über eine einzige Einheit. Die Aktivierung erfolgt automatisch beim Absetzen der Pfanne auf die Station oder den Verschiebewagen, die Gaszufuhr startet unmittelbar beim Kontakt der Kupplungsteile. Ein gefedertes System gewährleistet eine zuverlässige Verbindung, hohe Bewegungsfreiheit und bewährte Funktionalität unter anspruchsvollen Bedingungen. Eine verbesserte Pfannenführung erleichtert zudem die präzise Kranpositionierung – ohne Mehraufwand für den Kranführer.

Automatisches Schwerlast-Medienkupplungssystem

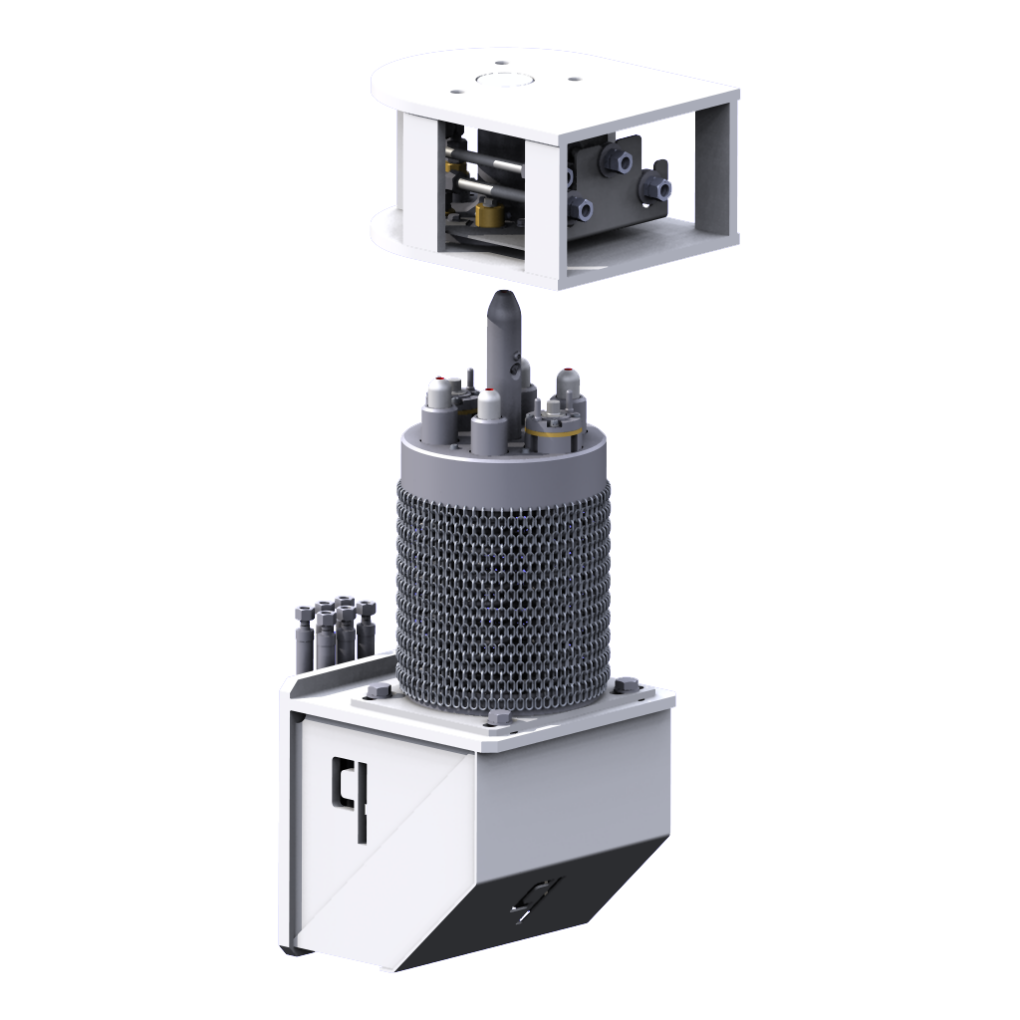

qoupler M

Der qoupler M ist ein patentiertes Kupplungssystem für verschiedene Prozessmedien wie Gas, Hydraulik, Strom und Flüssigkeiten. Er ist vollautomatisch, robust und sicher.

Der qoupler M ist das weltweit erste Kupplungssystem für mehrere Medien und den Einsatz in rauen und anspruchsvollen Umgebungen. Es überträgt automatisch verschiedene Medien wie Gas, Flüssigkeiten, Hydraulik, elektrische Ströme und Signale durch eine flexible und robuste Kupplungsverbindung. Als integriertes System stellt der qoupler M nicht nur die Versorgung von Stahlpfannen sicher, sondern macht auch manuelle Kupplungsvorgänge überflüssig.

Das federbelastete System sorgt für eine zuverlässige und schnelle Kupplung, während die hohe Flexibilität in alle Richtungen Toleranzen zwischen den Kupplungspartnern ausgleicht. Dank seiner staub- und temperaturbeständigen Ausführung ist das System optimal für den Einsatz in rauen Umgebungen geeignet.

Automatisches Schieberzylinder-Kupplungssystem

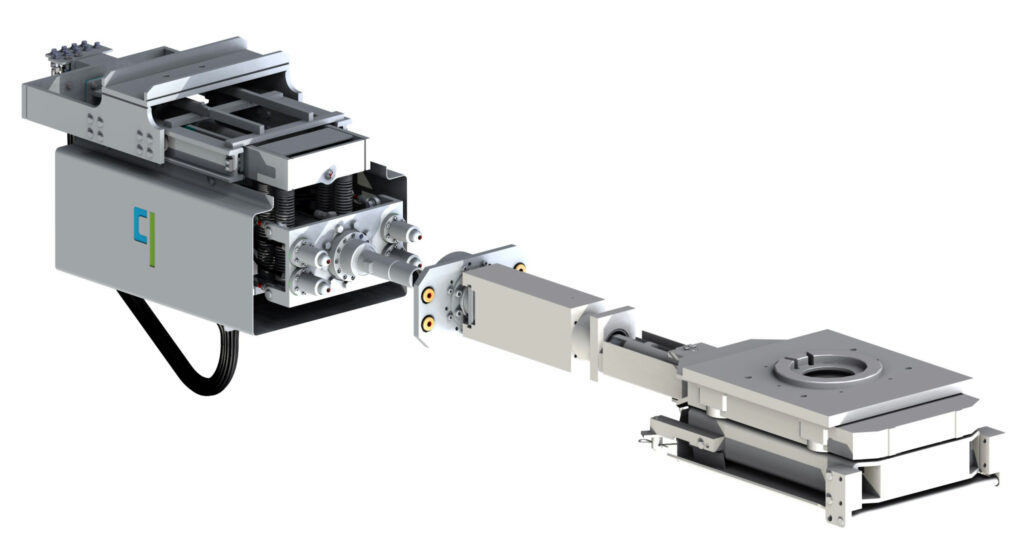

qoupler D

qoupler D koppelt den Hydraulikzylinder automatisch mit dem Pfannenschieber und ermöglicht so ein kontrolliertes Gießen von Stahl – ganz ohne manuelle Eingriffe oder komplexe Robotertechnik.

Das System koppelt den Pfannenschieber automatisch mit der Schiebersteuerung – über einen manipulatorgestützten Mechanismus, der keinen zusätzlichen Antrieb erfordert. Gleichzeitig werden alle relevanten Medien, der Schieberzylinder und die AMEPA-Technik angedockt. Eine flexibel gelagerte Arretierung ermöglicht dabei die Selbstzentrierung der Einheit.

Der kompakte Hub-Dreh-Antrieb ist mit einer integrierten Multimedien-Kupplung kombiniert, die während des Kuppelvorgangs Argon, elektrische Signale und den Schieberantrieb gleichzeitig verbindet. Hohe Bewegungsfreiheit in alle Richtungen sowie eine automatische axiale Ausrichtung sorgen für ein präzises Einkuppeln. Das robuste Design ist auf minimale Wartung und geringe Abnutzung ausgelegt.

Präzisionsgefertigte Mehrzwecklagerlösung

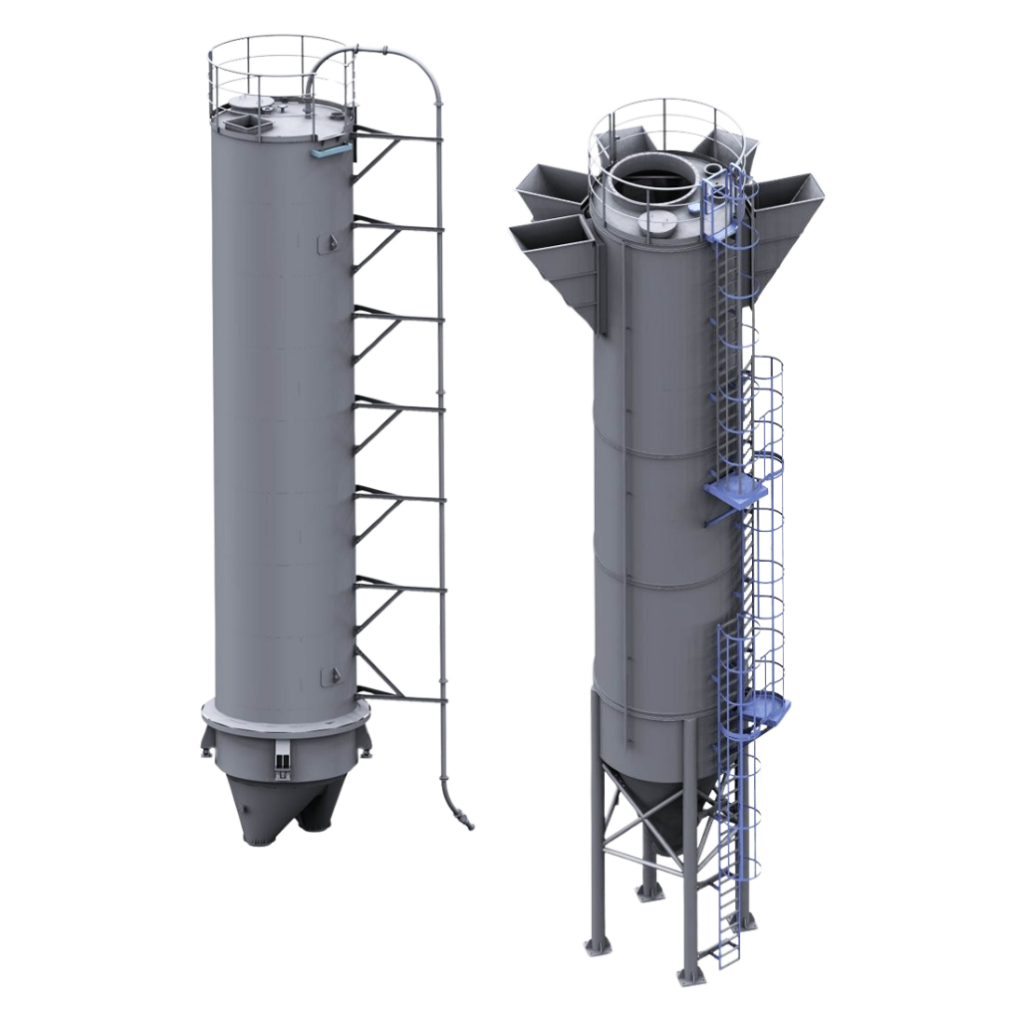

Silos und Behälterbau

Vom Konzept bis zur Fertigstellung. Wir liefern komplette Silosysteme für den industriellen Einsatz, einschließlich aller erforderlichen Komponenten und umfassender Unterstützung vor Ort.

Wir bieten umfassende Unterstützung entlang der gesamten Wertschöpfungskette – von Planung und Fertigung über Transport und Logistik bis hin zur finalen Montage. Unsere Silos und Behälter werden individuell an die Anforderungen jedes Projekts angepasst. Druckbehälter fertigen wir gemäß AD-2000-Norm, ausgelegt für Betriebsdrücke bis zu 10 bar. Plattformen und weitere Stahlkonstruktionen werden auf maximale Stabilität und Langlebigkeit ausgelegt.

Unsere Komplettlösungen beinhalten zudem Geländer, Zugangstreppen mit Rückenschutzkörben sowie Einblasleitungen mit Quetschventilen zur LKW-Befüllung. Optionales Zubehör wie Füllstandsanzeigen, Druckdetektoren, Filter, Austragshilfen, Vibroböden und Berstscheiben kann projektspezifisch ergänzt werden.

Maschinenbau | Basic & Detail Engineering

Engineering | Technische Dienstleistungen

Unser Ziel ist nicht, mit Großunternehmen zu konkurrieren, sondern komplexe Herausforderungen zu lösen, die Flexibilität und tiefes Ingenieurswissen erfordern.

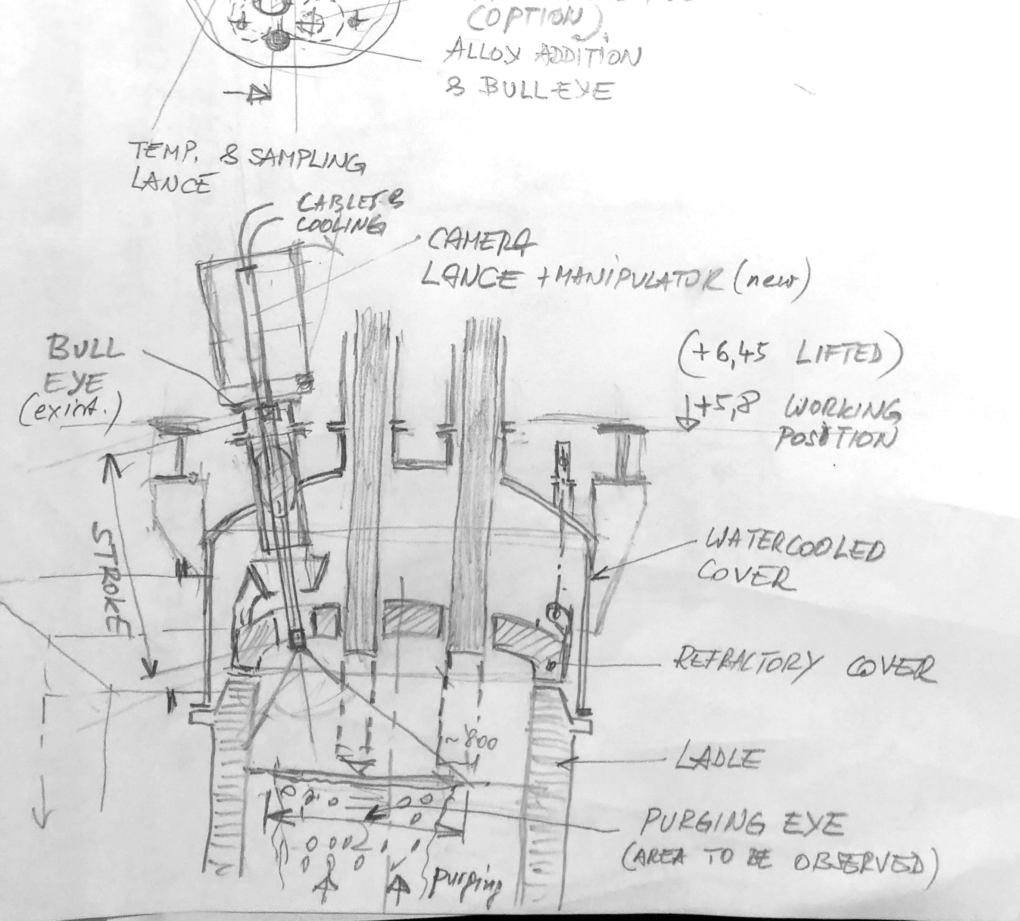

Wir unterstützen Stahlhersteller dabei, komplexe Anforderungen in funktionale und zuverlässige Konstruktionen umzusetzen. Unsere Dienstleistungen decken den gesamten Entwicklungsprozess von Maschinen und Anlagen ab – von der Konzeption über das Basic Engineering bis hin zur Detailplanung.

Mit einem starken Fokus auf metallurgische Prozesse entwickeln wir maßgeschneiderte Lösungen für die Primär- und Sekundärmetallurgie sowie für Block- und Stranggussanwendungen. Unsere Stärke liegt in Umbau- und Modernisierungsprojekten, bei denen Flexibilität, Schnelligkeit und ein tiefes Prozessverständnis den Unterschied ausmachen.

Durch die Kombination von praktischen Branchenkenntnissen und technischer Präzision stellen wir sicher, dass jede Lösung ihren Zweck erfüllt.