Digitalization of a Foundry’s Melt Shop

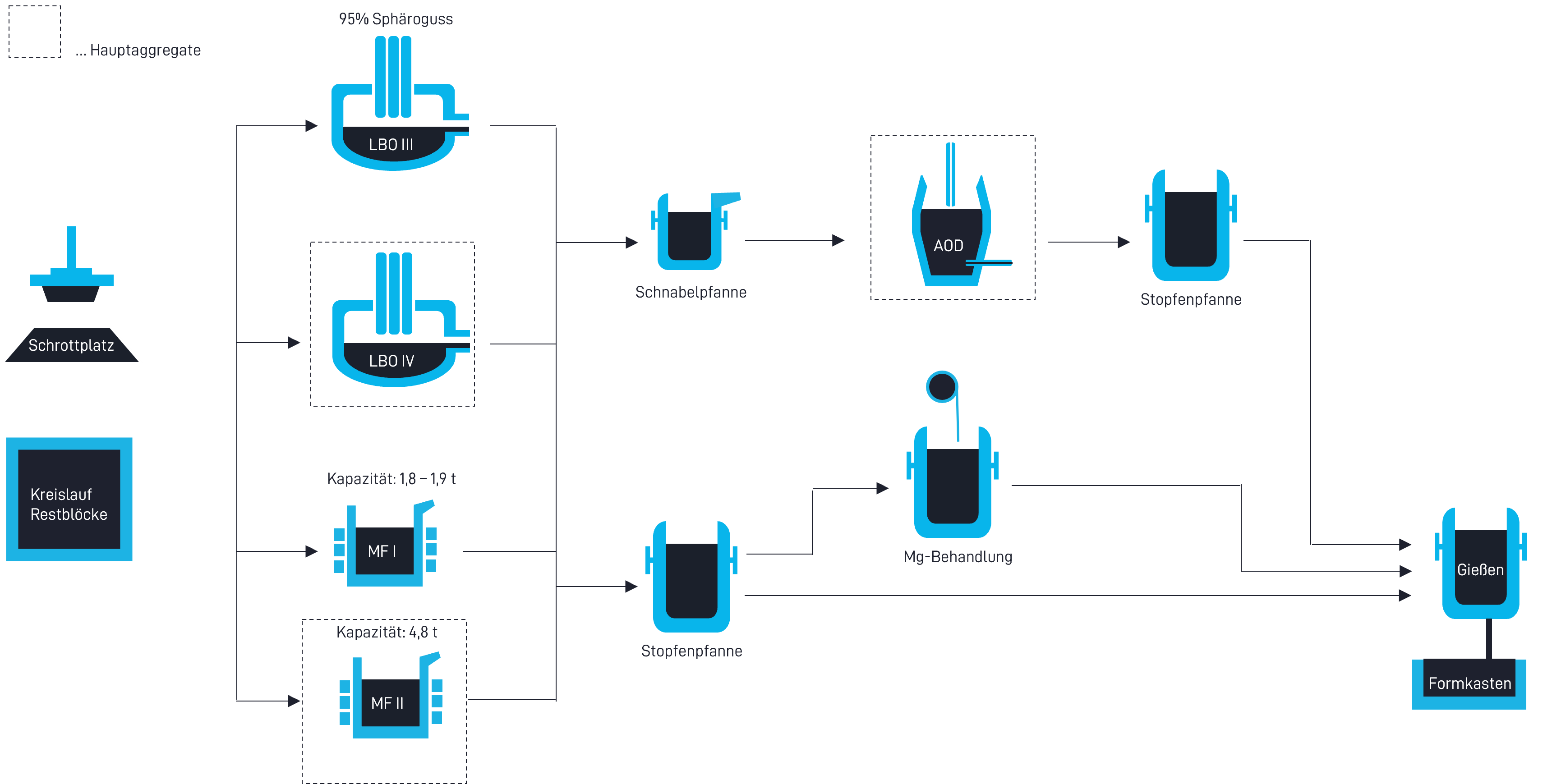

With the help of an integrated Level 2 and 3 software solution, process know-how was standardized and optimized, material supply security was ensured and resource efficiency was increased.

-

Business Unit

Software and Hardware

We digitize where it gets too hot for others: software by metallurgists for metallurgists. The starting point for our various solutions is our software framework qontrol. Due to its modular and microservices-based architecture, qontrol can be easily and quickly adapted to specific customer requirements.

-

Client

voestalpine Gießerei Traisen Gmbh & Co KG

-

Country

Austria

About the Customer

As an international player in the foundry industry, voestalpine Foundry Group, with its sites in Linz, Traisen (Lower Austria) and the joint venture in China, has made a name for itself worldwide. With a broad portfolio of steel castings, including nickel-based alloys, it offers customized solutions in areas ranging from energy production, such as hydro, offshore/wind or oil & gas, to machinery and railroad systems. By using state-of-the-art technologies and increasingly focusing on climate-friendly production processes, voestalpine Foundry Group is the first choice for cast products of the highest quality, in a weight range from a few kilograms to 200 tons.

Project Goal

The goal of the project was to integrate a software solution that closes the gap between the plant automation (level 1) and the ERP system (level 4) in order to

- track,

- control and

- optimize

dkwdlrfhdfhasdkljj