Transforming processes into customer-oriented software

Our modular software platform, qontrol, enables the digital mapping of all processes and process steps along the value chain under consideration (including raw materials, plants and machines). However, we also know that each of our customers has unique characteristics and specific manufacturing processes and that the one-size-fits-all approach is not applicable. qontrol is not a standard solution; it is tailored to the individual needs of our customers so that the following advantages can be achieved for production:

- Complete transparency of all processes thanks to seamless data recording

- Standardization of each individual process, as well as the entire chain

- Buildup and further development of process know-how

- Complete material management (consumption and stock)

- Tracking of the most important operating resources in connection with maintenance tasks

- Improved and transparent order planning (sequencing)

- Optimization of raw materials

- Minimization of energy inputs

- Reduction of process costs and maximized process efficiency

- Operator support by modern UX-driven GUIs

- Supervision and control of the processes

- Improved user-friendly reporting

- Possibility of advanced analytics

- Support for continuous improvement processes

- Product genealogy: digital linking of products and process data

The qontrol platform

Our software platform, qontrol, is based on the most modern software architectures, including the microservice principles and Industry 4.0 guidelines, and combines both Level 2 and Level 3 functionalities from the classic automation pyramid. In this way, the essential areas of the operational control level and the process control level are embedded in a modular software platform.

Process control level

Data communication

We understand connectivity to be the logical points of contact of our software solution with external systems. Since the degree of automation in the manufacturing and processing industries often differs from application to application, this variability must be taken into account in a highly modular and generic architecture of data recording. The interface manager is an independent solution that can be installed and configured specifically for every customer. ERP systems, LIMS, machines and plants, intelligent sensors and other customer-specific systems can be quickly and efficiently connected to our software system.

Production tracking

With the help of this software component, all process-related data, downtime, resources and materials, as well as semi-finished products, are recorded. During production, the status of production (where and how products are manufactured or processed) is available or known at all times. Definable quality criteria can be evaluated in real time, and possible problems can be identified at an early stage. Complete production traceability production is guaranteed because all data is stored centrally. Subsequently, this data can be easily and holistically evaluated and analyzed.

Process manager

The process manager is the digital mirror image (the digital twin) of the individual processes. It contains both static and dynamic information. Static information can be specifications of process parameters, work instructions, quality criteria or target values. Dynamic information changes over time as the production processes progresses. In the process industry, these have to be calculated using specific models. Thus, the physical manufacturing process can be assessed, analyzed, predicted and optimized. To do this, the process-relevant data from the physical world must be transferred to the models. The simulation data are visualized, and depending on the degree of integration, the process can be controlled.

Operational management level

Master data management

The master data management enables the definition and administration of all the necessary parameters to answer the following questions:

- What should be produced?

- How must the product be produced?

- What resources are needed for this?

Know-how management is at the heart of master data management. It defines how a particular product can be made. For this purpose, process-specific instructions for each step (recipes) can be defined and combined into a production workflow. The products themselves are maintained in the product definition. The raw materials and the equipment (machines/systems) are managed in the resource management module. The locations where the resources are stored are also managed.

Production dispatching

The production dispatching module merges master data, such as the product to be produced, the required resources and the workflow (i.e., the process-specific recipes) using production orders. These production orders can be received by an external system, but they can also be created manually. For a defined planning horizon, the order sequencing module enables the manual generation of a defined production sequence based on all available production orders.

Performance analysis

All cyclically recorded process data and events and material movements, as well as the equipment used, are stored in the database centrally and in relation to the production order. This production data stored in the database is converted into customer-specific KPIs and metrics, and it is made available in the form of trends, dashboards and reports that can be shared with other information systems. This means that all production data is analyzed and prepared so that it can be used to make decisions, evaluate your performance and support the continuous improvement process.

When to contact us

qontrol is a modular platform that can be applied well to different industries.

Main platform features are as follows:

- A modern platform developed with latest design principles and a microservice architecture.

- Scalable and expandable setup with easy upgrade possibilities.

- Web-based client with responsive design.

- Standardized and well-documented APIs to interface with third-party applications.

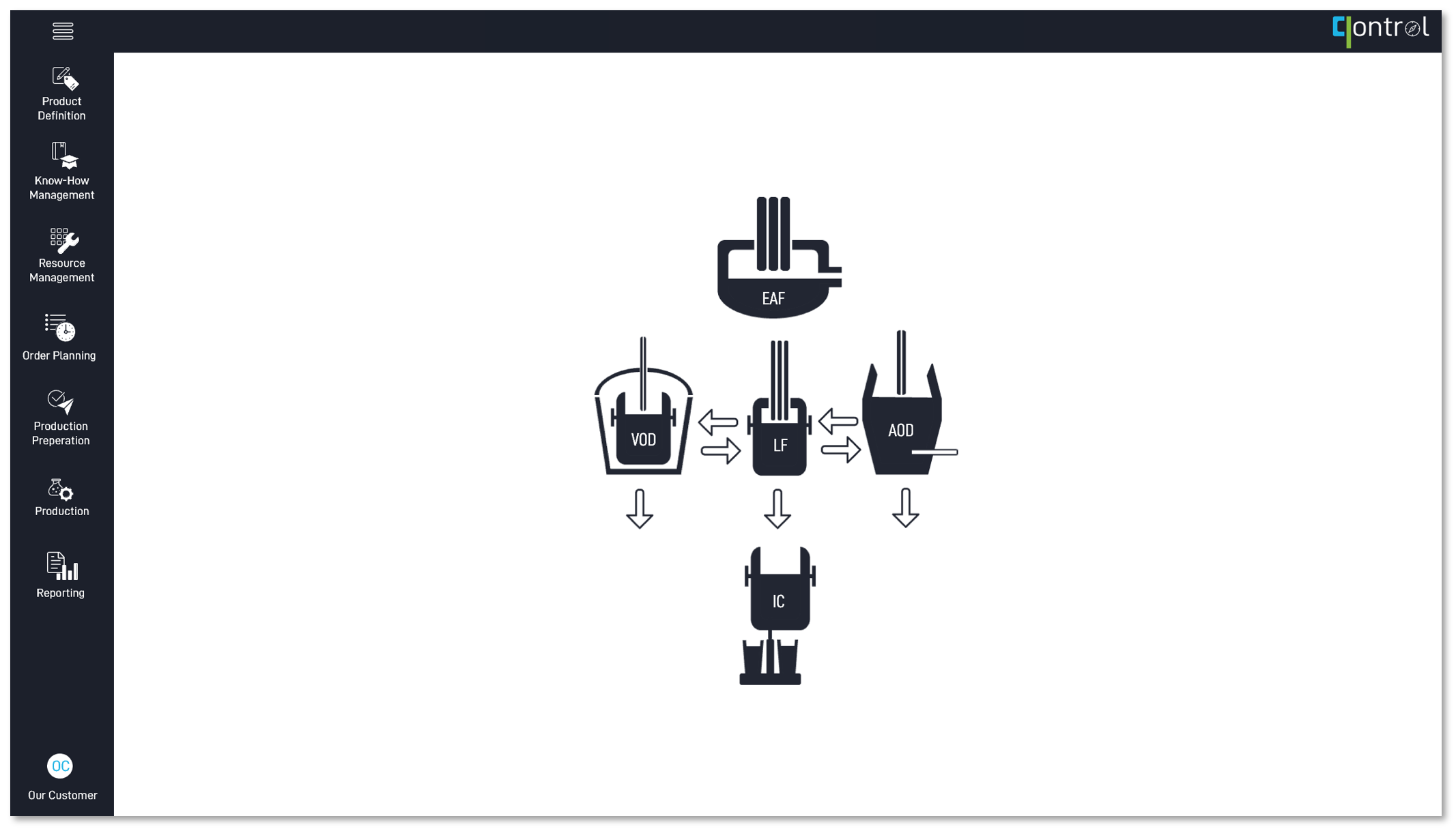

qontrol for steelmaking

qontrol for steelmaking is a comprehensive and holistic solution that takes into account the different requirements of the process control level (control and optimization of the metallurgical processes) and operational management level (administration and planning). qontrol combines both Level 2 and Level 3 functionalities from the classic automation pyramid in a modular single source software solution.

Level 2 functionalities

Process data is received and recorded in real time via a flexible and quickly adjustable interface. Statically or dynamically calculated setpoints can be sent to the system automation (Level 1). Process-specific cockpits are graphical user interfaces (GUI) in the control rooms, and/or our full-HD touch operating terminals qonsole outside the control rooms enable interactions with the operator (user). The software system performs the following tasks at the process control level:

- Tracking of heat orders, process data and events, material (scrap, alloys, slag formers, wire) and operating resources such as ladles, lances, molds, etc.

- Process supervision of the metallurgical processes by comparison of target and actual figures and evaluation of quality rules.

- Modeling of the different metallurgical processes (mapping of the actual state of melt and slag).

- Control of the process using the setpoints and work instructions defined in the production workflow module – i.e., compilation of the process-specific recipes (melting, refining, degassing, etc.).

- Controlling and optimizing the processes by means of dedicated dynamic setpoint and optimization models.

Operational management

All information about the product to be produced, as well as all information that are necessary for the production of the products (how to produce the products), are created and managed here. The management and creation of the necessary resources (raw materials and operating resources) is made possible by the resource management modules. In addition, all basic material and warehouse management functionalities, including inventory management, are available.

Production planning is also part of the operational management module. This includes receiving heat orders, managing them and creating a production sequence. The production dispatching module ensures that the raw material recipes and the operating resources to be tracked and prepared are linked to the heat orders. The performance analysis modules offer heat-specific and product-specific reports. Key figures and KPIs are automatically generated by the system for each heat and product. Ultimately, KPIs are clearly visualized in the form of dashboards and, therefore, can be compared and analyzed quickly and easily.

Master data management

- Product definition: A product is defined by its composition, (geometry) shape and properties. Thus, this module enables the definition and administration of steel grades, dimensions and properties. Steel grades can either be transferred from an external system or created, specified and maintained in qontrol. The specification includes the chemical composition with min and max values, steel grade-specific parameters and the assignment of production workflows. Grades can also be structured in the form of a family tree. This enables the assignment of workflows at different levels of the structure and, thus, the possibility of inheritance. Geometry refers to the dimension of the ingots (in case of ingot casting) and to the cross-section parameters of billets, blooms or slabs (in case of continuous casting). Since casting setpoints strongly depend on geometric parameters, this module links the product’s geometry with grades and casting recipes.

- Know-how management: Here, the user can define the recipes (instructions) for the respective metallurgical processes. With the recipes, all necessary actions, parameters and treatment targets can be defined in order to standardize production. This information is initialized automatically on the cockpits and displayed for the operating personnel. The assembling of recipes results in a production workflow. These workflows can be assigned to a single steel grade, a steel grade family (according to the defined tree structure) or to any group of steels defined by the authorized user. Versioning of recipes and workflows will be done automatically by the software system.

- Resource definition: This module enables the administration and creation of all information about the necessary resources for the production of the steel products. Specifically, this is the master data management for raw materials, consumables and operating resources. In addition, all basic functionalities of material and storage location management are provided. Raw materials are those materials that are technically necessary along the production route in order to produce the defined steel grade (e.g., scrap, alloys, slag formers, wire). Consumables are those materials that are consumed during steel production but are not used explicitly for adjusting the chemical analysis (e.g., refractory material, electrodes, casting powder). Operating resources are all machines, equipment and other devices that are directly or indirectly involved in the manufacturing process (ladles, scrap baskets, molds, plates, etc.).

Production dispatching

- Raw material disposition: Based on the heat to be produced, the loading instructions (raw material input for EAF or BOF) can be created either (1) on the basis of the standard raw material input or (2) using our raw material optimization module. The former is useful under constant market conditions (raw material costs) and unlimited availability of raw materials, while the latter takes into account the current raw material costs as well as the current inventory. Once generated, the loading instructions are then assigned to the heat order and are transmitted to the scrap yard cockpit after approval.

- Casting set-up disposition: For ingot casting, the entire casting setup (plates, molds, trumpets) must be prepared in advanced for the specific production (heat) order. Based on the information available in the heat order regarding the ingots to be produced (number and format), a standard casting setup can be assigned to this order. After checking and approval (and possible changes), the casting setup information is transferred to the casting preparation software module (IC cockpit). Thus, the preparation of the entire casting equipment in the casting area is supported and, complete lifecycle tracking of the operating resources is guaranteed.

- Heat order sequencing (planning): Heat orders can either be received by an external system or created manually in the software by an authorized user. These orders are clearly displayed and serve as an order backlog for the creation of a sequence of heat orders to be produced within a defined time horizon. The sequence planning is done in a dedicated module and, optionally, can be validated by executing simple rules. Violation of rules will be reported by the system. The sequence planning can be adjusted at any time. Another functionality of sequence planning is deviation management, which supports the operator when it is necessary to readjust heat orders during production. Based on a current chemical analysis of the melt, the system proposes possible orders that can be produced with this chemical analysis. If no possible order is found, a possible steel grade is suggested from the total of the grades defined in the system.

Reporting and performance analysis

- Heat reports: The system automatically creates heat-specific reports in which all relevant process data (cyclical data and events), sample analyses, consumption and operating data are summarized for each individual metallurgical plant. The information is provided in the form of numerical values and diagrams (charts). In addition to the process-specific data and key figures, information about the recipes used is available to illustrate the comparison of the actual performance with the target performance.

- Product reports: The product reports provide an overview of the products produced, including all product-relevant key figures. The functionalities are identical to the heat reports and enable queries for a defined period, as well as queries based on heat and product number. The application displays a complete product genealogy.

- Comparative reporting (production analysis): Based on the recorded process data of each heat produced, this module offers an extended reporting tool (KPIs) and enables the comparison of heat-specific KPIs within a defined period. By selecting a time range (e.g., a specific day, the last week, the last month, etc.), the heats produced can be compared with each other. Heat-specific KPIs and key figures can be visualized and compared very easily.

When to contact us

qontrol for steelmaking is a software platform that was developed specifically for the steel industry. It seamlessly integrates the advanced raw material optimization module and the metallurgical models to guide, control and optimize metallurgical processes. Furthermore, qontrol covers all necessary workflows from master data management to the planning of the heats to be produced. qontrol can be customized to suit individual needs and integrated into the existing IT system landscape. Typical application examples of the modern qontrol platform are as follows:

- A holistic software system that – as a single-source solution – maps all the functionalities between the equipment automation and the ERP system (Level 2 and Level 3 functionalities).

- A new Level 2 system for the entire production route.

- A new Level 2 system for a specific metallurgical process that also takes into account other existing Level 2 systems and the IT landscape.

- A modular software system that can be integrated and expanded in stages.

- A software platform developed by a company that combines expertise in the areas of metallurgy and software development.

qontrol for Finishing Lines

Coming soon – stay tuned for further updates!

qontrol for Copper Production

Coming soon – stay tuned for further updates!