Automatic Gas Coupling System

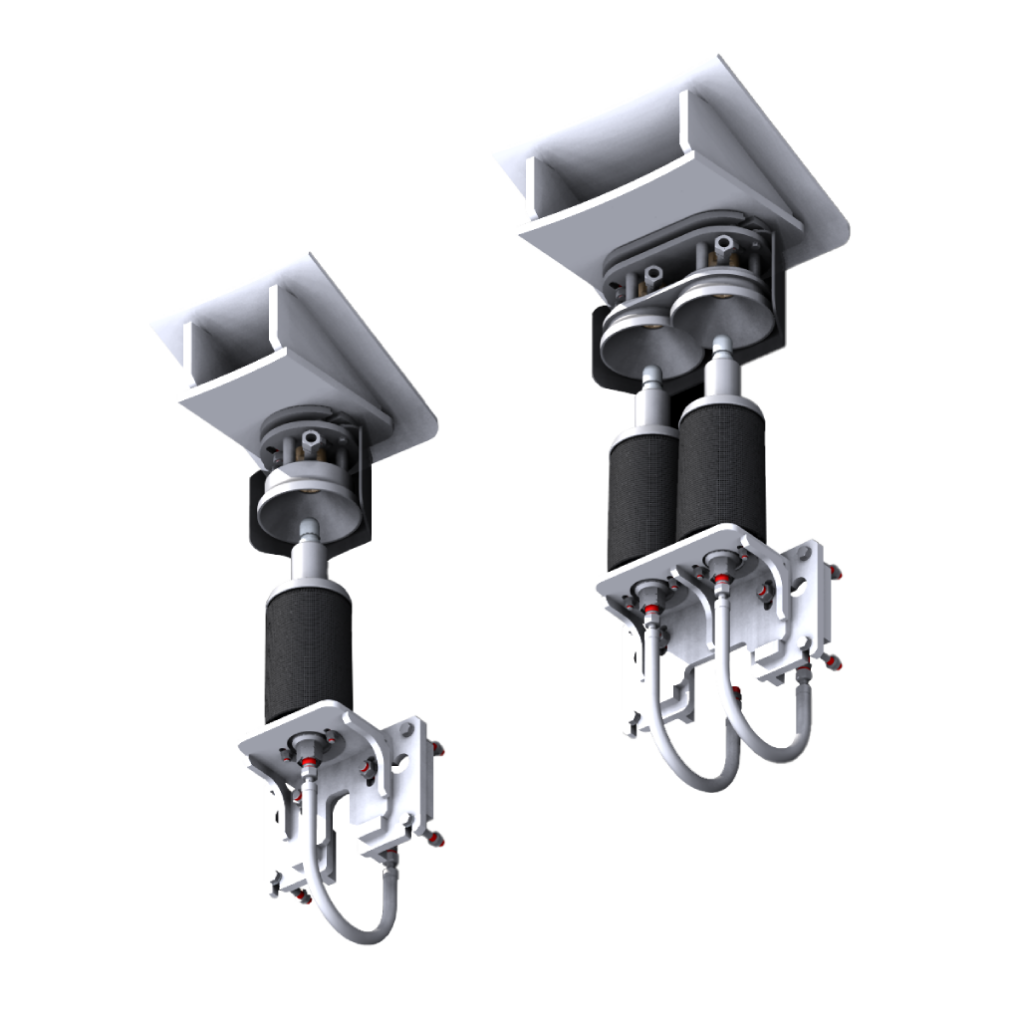

qoupler G

qoupler G automatically connects the gas supply to steelmaking ladles. It increases operator safety and ensures a secure and reliable connection.

The qoupler G is an advanced, automatic gas coupling system that guarantees speed, safety, and reliability. Tailored for demanding environments, such as steel mills, it guarantees optimum performance in harsh conditions. The system is easy to install and adapt to existing setups, ensuring smooth operation and maintenance.

It is suitable for all ladle sizes and flow requirements, coupling up to three supply lines via a single unit. Activation is automatic when the ladle is placed on the station or transfer car, and the gas supply starts immediately upon contact of the coupling parts. A spring-loaded system ensures a reliable connection and high freedom of movement, as well as proven functionality under demanding conditions. Improved ladle guidance facilitates precise crane positioning without additional effort from the crane operator.

Automatic Heavy-Duty Multi-Line Coupler

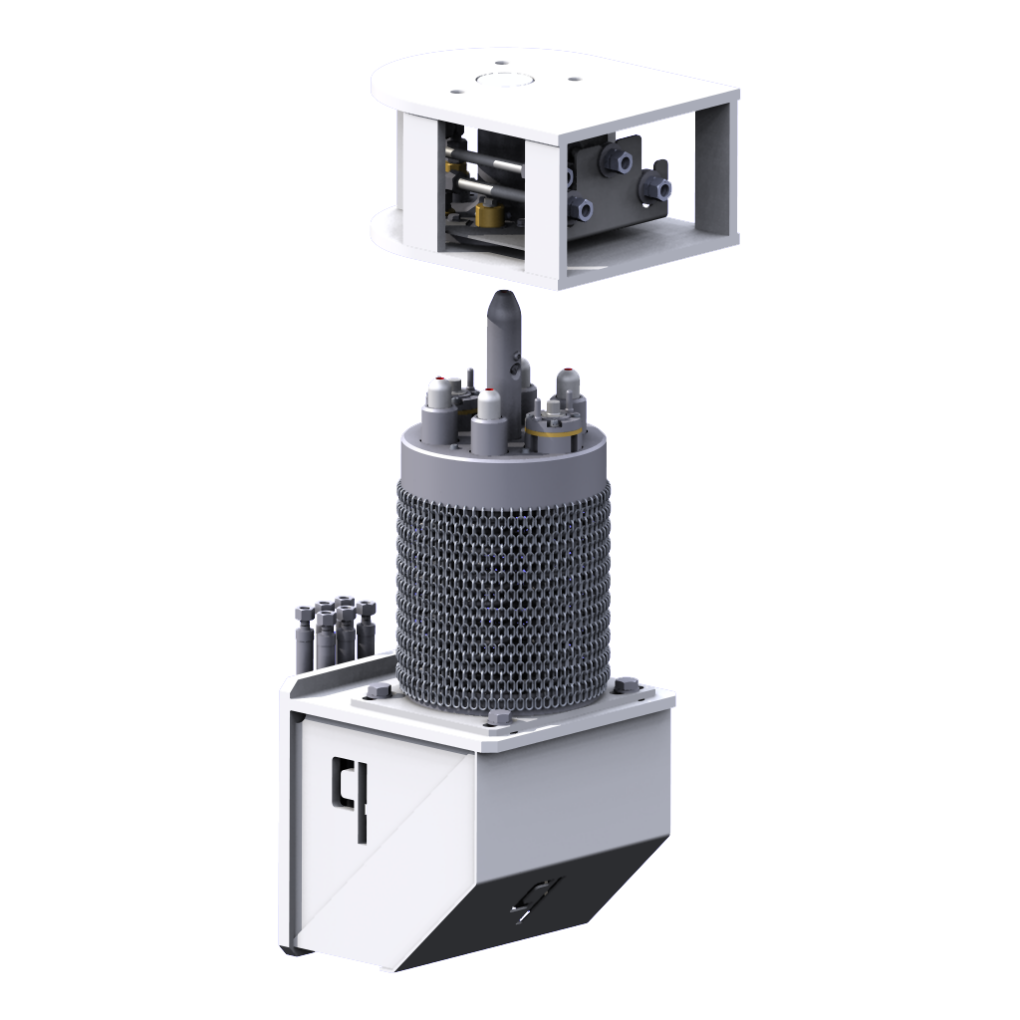

qoupler M

qoupler M is a patented multi-media coupling system for the safe and efficient supply of several media such as gas, liquids, hydraulics and the transmission of power and signals.

qoupler M is a patented multi-media coupling system that connects gas, hydraulic, electric, and fluid lines in a single step. Designed for demanding environments like steel plants, it eliminates manual hose and cable handling by automatically supplying all required media during ladle placement.

The system compensates for misalignment and ensures secure coupling with spring-loaded flexibility in all directions. It is highly adaptable, dust and heat resistant, and optimized for integration into ladle handling stands, transfer cars, or furnaces.

Automatic Slide Gate Coupling System

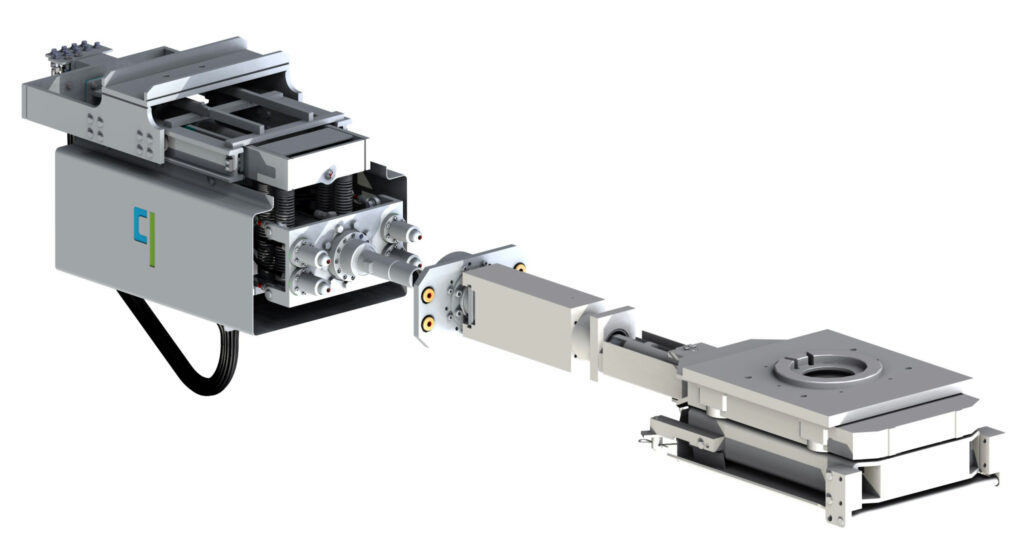

qoupler D

qoupler D is a globally unique solution that automatically couples the hydraulic cylinder with the ladle slide gate. This enables the controlled casting of steel - without any manual intervention or complex robot technology.

The system combines maximum safety with efficient operation by connecting the slide gate drive, gas supply, and control signals in one smooth step. No manual work is needed, and complex robotics are not required.

Installed on the ladle turret or ingot casting car, the system aligns itself automatically, compensates for misalignment, and ensures secure coupling with minimal wear. qoupler D is built for the casting floor, where safety is critical.

Multi-Purpose Storage Solution

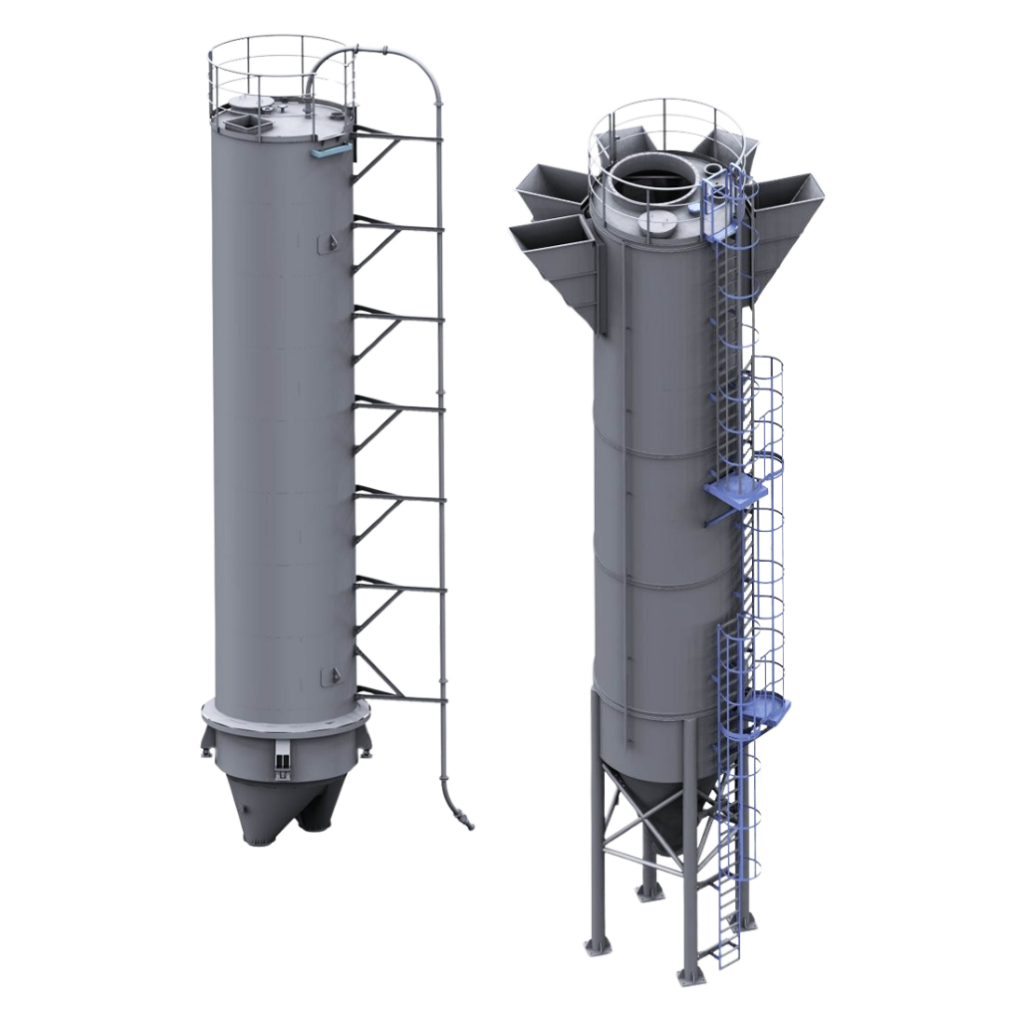

bins & silos

From concept to completion. We deliver complete silo systems for industrial use, including all required components and full on-site support.

We design and deliver bins & silo systems tailored to your material, process, and site requirements. Our services cover every step – from structural analysis and engineering through manufacturing, transport, and final erection.

Each system includes all necessary components, such as hoppers, platforms, valves, level sensors, discharge equipment, and safety features. With robust design and practical integration, our silos provide reliable storage for a wide range of industrial applications.

Expert Engineering & Manufacturing Solutions

engineering services

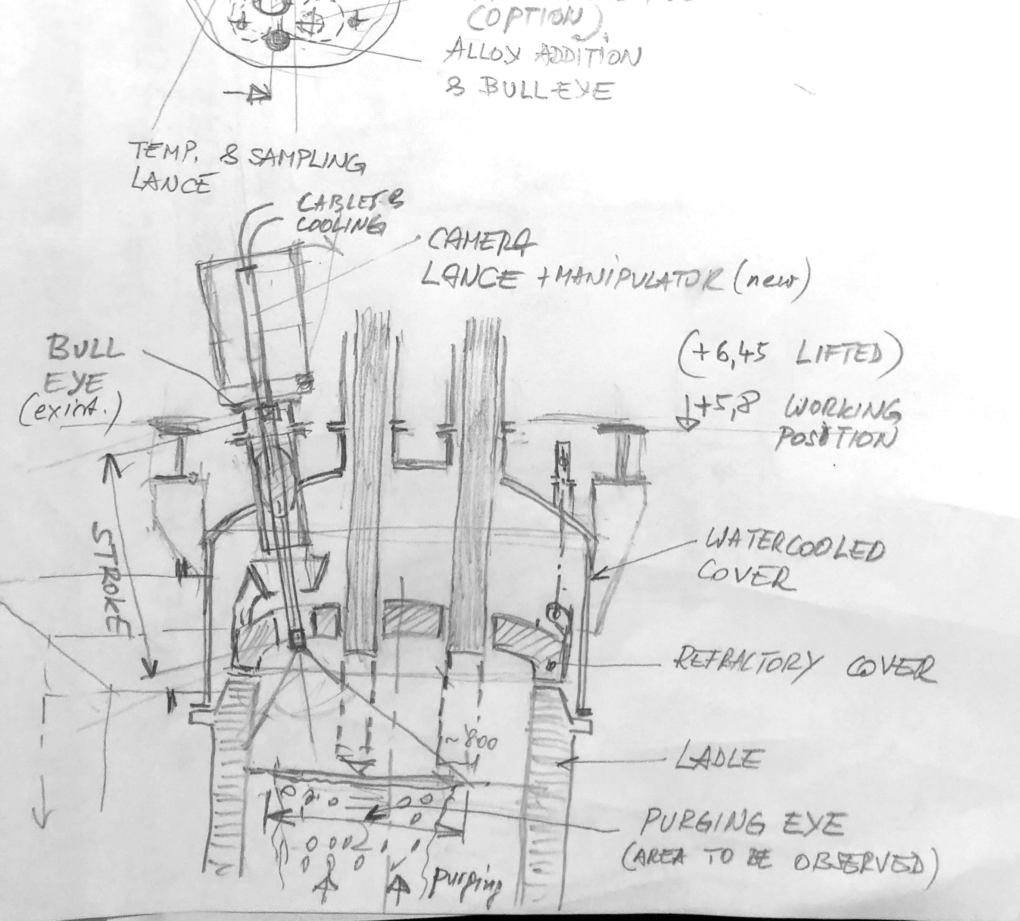

We are not here to compete with size. We are here to solve complex problems where flexibility and engineering depth are key.

We support steelmakers in turning complex requirements into functional and reliable designs. Our engineering services cover the full development process of machines and systems – from conceptual design through basic and detailed engineering.

With a strong focus on metallurgical operations, we develop tailored solutions for primary and secondary metallurgy, as well as for ingot and continuous casting applications. Our strength lies in modification and revamp projects, where flexibility, speed, and deep process understanding make the difference.

We combine practical industry knowledge with engineering precision to ensure that every solution fits its purpose