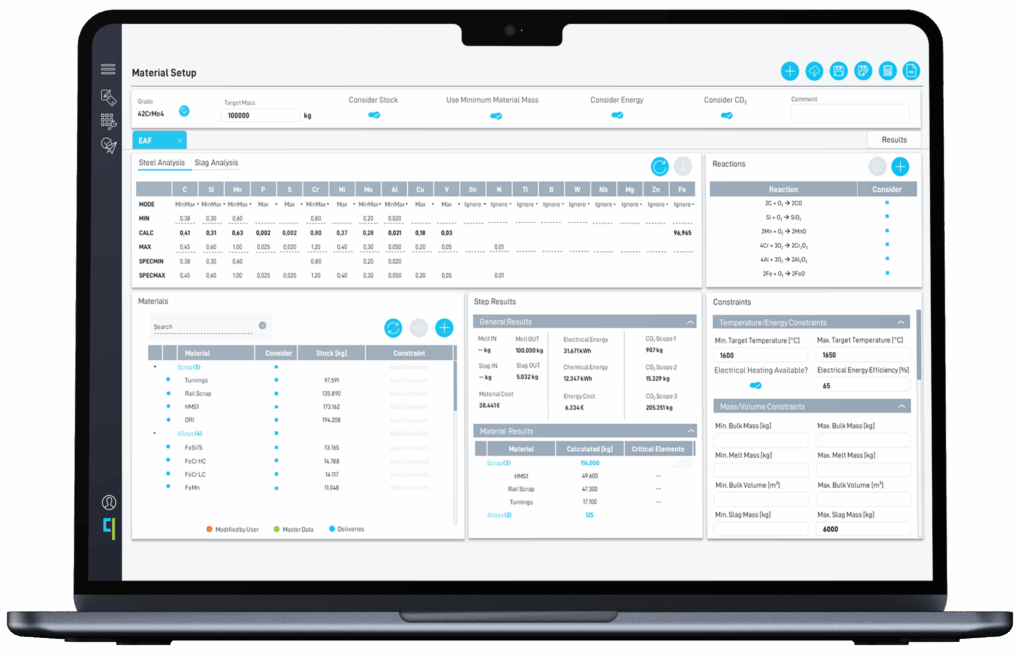

Raw material management software

qontrol maps

Automated scrap characterization, improved transparency and optimized use of raw materials from melting to the casting process.

qontrol maps is an advanced raw material management and optimization system for meltshops. It connects real-time scrap characterization, charge and alloy optimization, and campaign planning to help you make better decisions at every step of steel production.

The system considers process constraints, raw material properties, energy costs, and metallurgical reactions to generate ideal charge mixes and production sequences. It helps reduce cost, energy use, and CO₂ emissions across the full value chain.

Level 2 software system for steel plants

qontrol steelmaking

Control and optimization of steel production processes with state-of-the-art software, sound metallurgical models and artificial intelligence.

qontrol steelmaking is a modular Level 2 software for controlling and optimizing the entire steel production process. The software enables intelligent automation based on live production data, digital twins and adaptive target values.

With qontrol steelmaking, yield, process stability and energy efficiency can be increased in a targeted manner. At the same time, raw material costs and CO₂ emissions are reduced while the use of alloys is optimized. The solution also ensures end-to-end traceability through automated validation and consistent process control.

The software solution can be seamlessly integrated into existing automation layers and company systems, supports common industry protocols and can be used flexibly as an individual module or comprehensive overall solution - locally or cloud-based.

Manufacturing Execution System

qontrol MES

Orchestrated processes, seamless system integration and data-supported optimization for maximum efficiency in steel production.

qontrol MES is the digital heart of production. It links all processes - from resource planning to quality assurance - and ensures smooth processes in real time. As the central link between the ERP system and process automation (Level 2/SCADA), qontrol MES creates transparency, increases efficiency and enables well-founded decisions based on current production data.

qontrol MES orchestrates the entire production process, ensures clear workflows and a consistent information model across all systems. Another central component is the integrated master data management: products, raw materials, storage locations, equipment and machines are managed reliably and consistently. This creates a stable backbone for modern, integrated steel production.

Ladle Management Software

qontrol LMS

Make every ladle count: for more safety, less downtime, and smarter decisions.

qontrol LMS is a smart solution for efficient and safe ladle anagement in steel production. The system enables real-time tracking of every ladle and detects wear and potential risks early on, thus supporting safe operation. By analyzing temperature, maintenance intervals, and refractory material data, qontrol LMS extends the service life of ladles, reduces downtime, and lowers maintenance costs. Thanks to its modular structure and seamless integration, ladle management becomes a stable, data-driven component of an optimized production chain.

Intelligent Camera System

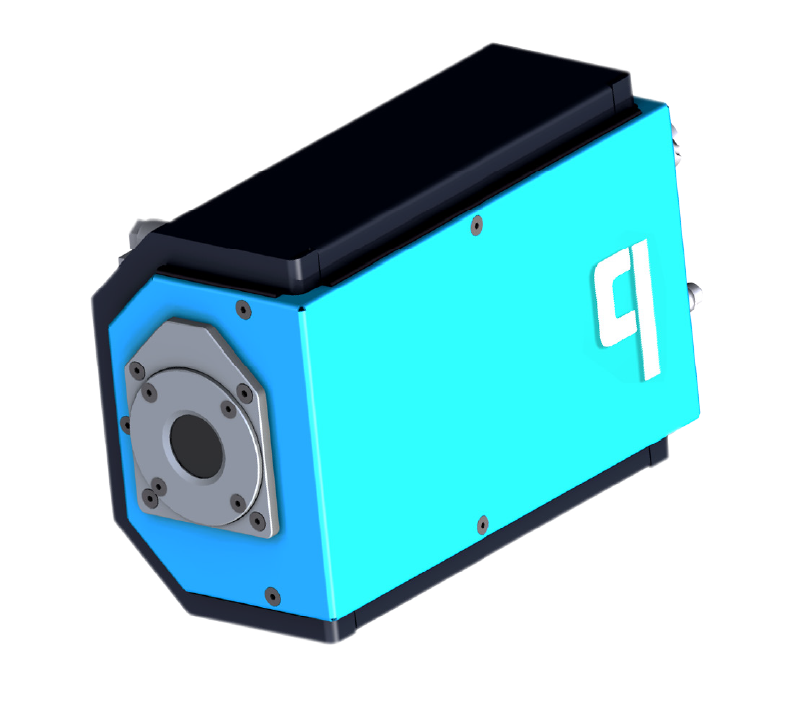

qurve

Our camera solution enables precise object detection and condition monitoring. It can be used as a stand-alone solution or integrated into the qoncept software.

qurve is an intelligent, camera-based sensor system that has been specially developed for harsh industrial environments such as steelworks. Thanks to its compact, dust-tight design, effective cooling and minimal maintenance, qurve is a reliable solution even under extreme conditions.

The system can be quickly and easily integrated with our qontrol software platform or other systems. Thanks to the implemented signal processing, qurve automatically detects objects without the need for invasive marking methods.

Typical applications include the automatic identification of ladles at metallurgical plants, furnaces and maintenance sites, the detection of railroad cars in scrap yards and the seamless tracking of products across various production stages. In addition, qurve enables real-time tracking of the movements of cranes and other mobile objects by automatically determining their coordinates.

Operating Terminals

qonsole

qonsole is the industrial terminal for smart plant operations. Touch-enabled, heat-resistant and fully connected, it keeps your systems and your people in sync.

qonsole is the rugged operator terminal designed for harsh environments. Featuring a full HD display and rugged steel housing, it combines reliability and ease-of-use in a single device. From real-time system monitoring to production control using state-of-the-art software, qonsole keeps operators informed and connected. It supports flexible mounting, glove-compatible input and seamless integration via Ethernet, Wi-Fi or LTE.